Installation and Usage:

- Before use, check whether the components are damaged during transportation, and then install and use.

- During installation, pay attention to whether the medium flow direction and the thread type of the pipe are correct (the medium must be filtered through a filter screen of 40μm or above).

- Pay attention to whether the installation conditions meet the technical requirements (such as rated voltage, operating frequency, working pressure, operating temperature range, etc.), and then install it horizontally.

- Try to avoid using it in a vibrating environment and pay attention to anti-freezing measures in low temperatures.

Specifications

|

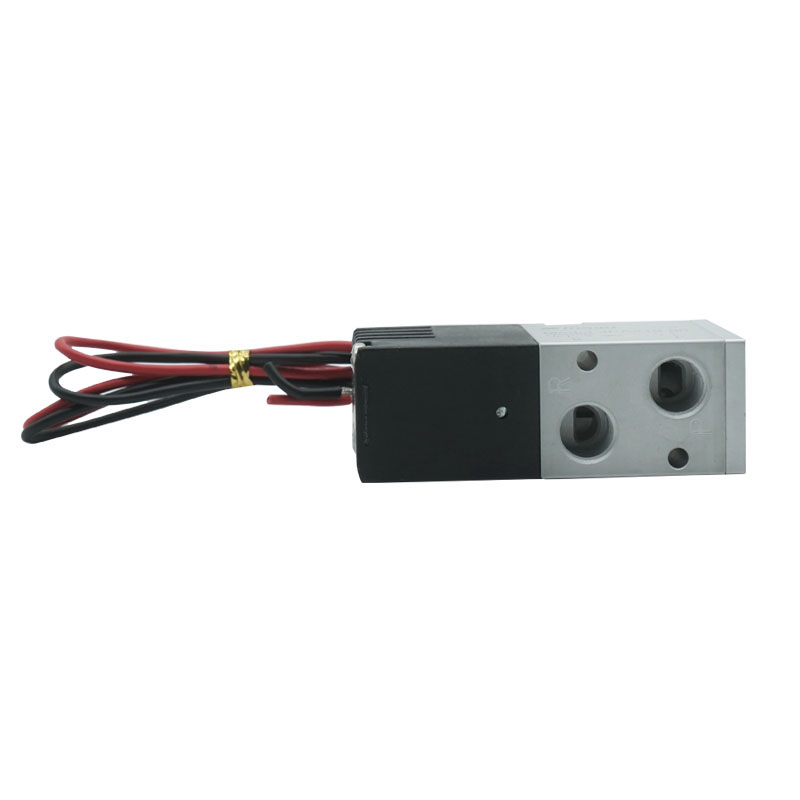

Appearance |

Compact structure |

|

Product type |

Large flow two-position three-way high-frequency reversing valve |

|

Body material |

Aluminum |

|

Excuse method |

Thread (G1/8″ NPT is also available) |

|

Pipe diameter |

Inlet = outlet = exhaust = G1/8″ |

|

Working medium |

Compressed air (filtered above 40μm) low vacuum |

|

Action |

Direct acting |

|

Process temperature ℃ |

5~50C |

|

Power connection method |

Lead-type power connection |

|

Power |

1.8W |

|

Working voltage |

24V DC±10% |

|

Working pressure |

-1~7bar |

|

Pressure resistance |

1.0MPa |

|

Oil supply |

No oil supply |

|

Ambient temperature |

-5~50℃ (not frozen) |

|

Usage environment ℃ |

Cannot be used in corrosive gas environment |

|

Protection level |

1P65 |

|

Working temperature ℃ |

-5~50℃ |

|

Response time |

≤20ms |

|

Applicable cylinder |

16-40 |

|

Note: The response time is the value tested at a pressure of 5 bar and without oil supply. |

|