Stainless Steel 6-inch Pneumatic Butterfly Valves Introduction

Pneumatic butterfly valves are essential components in industrial fluid control systems, offering precise regulation of liquids and gases. These valves use compressed air to operate, making them ideal for automated processes where speed and reliability are critical. The butterfly valve's simple yet effective design—a rotating disc mounted on a central shaft—ensures quick shut-off and minimal pressure drop, making it a popular choice across industries.

What is a Pneumatic Butterfly Valve?

A pneumatic butterfly valve is a quarter-turn valve that controls flow using a circular disc positioned in the center of the pipe. When the actuator rotates the disc 90 degrees, it either allows full flow or completely blocks it. This design is particularly advantageous for large-diameter pipelines, where space and weight constraints matter. Industries like water treatment, chemical processing, and oil & gas rely on these valves for their efficiency and durability. Unlike manual valves, pneumatic versions enable remote operation, reducing labor costs and improving safety in hazardous environments.

Why stainless steel pneumatic butterfly valve?

Stainless steel is the material of choice for high-performance butterfly valves due to its exceptional corrosion resistance, strength, and longevity. In aggressive environments—such as those involving seawater, chemicals, or high temperatures—stainless steel outperforms alternatives like cast iron or carbon steel. Additionally, its smooth surface minimizes bacterial growth, making it indispensable for food, pharmaceutical, and sanitary applications. HANUMAN's stainless steel valves ensure compliance with stringent hygiene standards while reducing lifecycle costs through minimal maintenance.

Focus on the 6 inch pneumatic butterfly valve Specification

Valve sizing is critical to system efficiency. A 6-inch (DN150) pneumatic butterfly valve strikes a balance between flow capacity and compact design, fitting seamlessly into mid-scale industrial pipelines. This size is commonly used in water distribution, HVAC systems, and chemical processing plants. Choosing the right diameter ensures optimal pressure management and prevents issues like cavitation or excessive wear. HANUMAN’s 6-inch valves are engineered to meet GB/T13927-92 leakage standards, guaranteeing tight sealing even under fluctuating pressures.

Key Features and Advantages of HANUMAN D671X/D641X Series

Operational Efficiency and Reliability

The D671X/D641X series delivers rapid response times, achieving full opening or closing in seconds—a crucial feature for emergency shut-offs. Its robust construction reduces vibration and noise, enhancing operational stability. The valve’s streamlined design requires no lubrication, cutting downtime for maintenance. With fewer moving parts than gate or globe valves, it’s less prone to failure, translating to lower total cost of ownership.

Ease of Use

These valves feature a lightweight, space-saving design that simplifies installation in cramped areas. The soft-seal mechanism (NBR-lined) ensures bubble-tight shutoff, even with low-pressure gases. Users benefit from minimal fluid resistance, which maintains high flow rates while reducing energy consumption. The pneumatic actuator allows integration with PLC systems for automated control, supporting Industry 4.0 initiatives.

Construction and Design

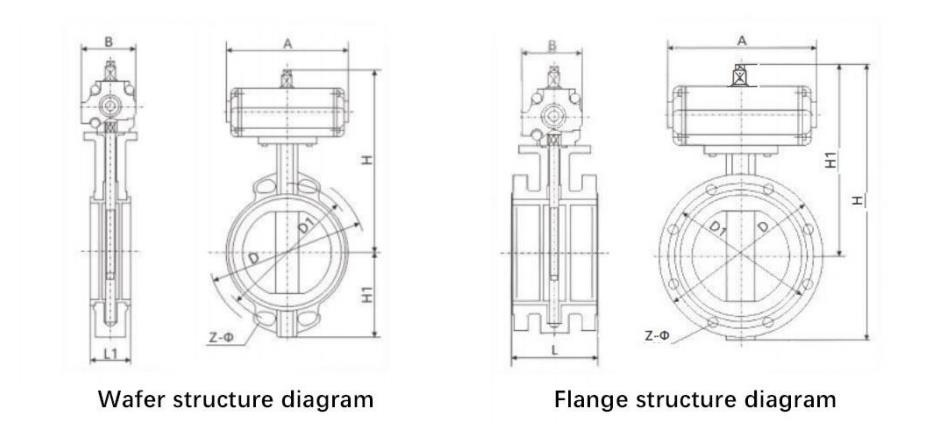

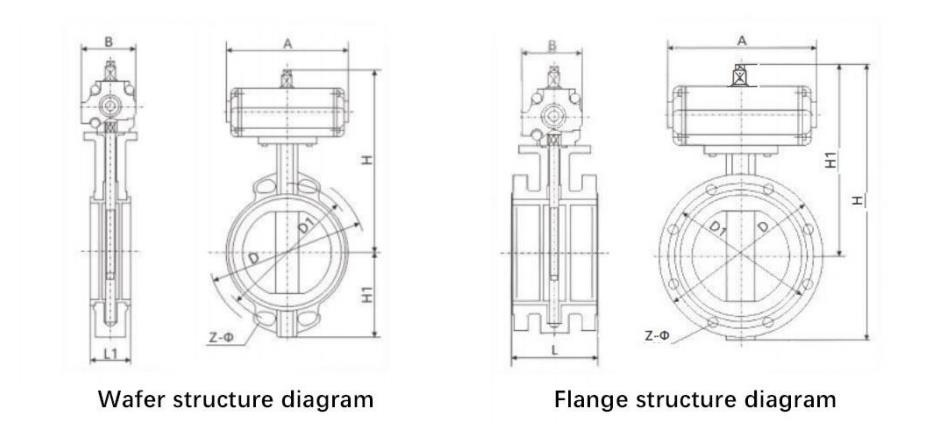

Available in wafer and flange types, the series caters to diverse piping configurations. Wafer valves are cost-effective for compact systems, while flanged versions provide superior sealing in high-pressure applications. Both designs use high-grade stainless steel for the body and disc, paired with flexible graphite seats to withstand thermal expansion.

Detailed Specifications and Material Options

Dimensional and Pressure Specifications

The valves cover nominal diameters from DN50 to DN800, with the 6-inch (DN150) model being a bestseller. Pressure ratings include 0.6 MPa, 1.0 MPa, and 1.6 MPa options. A dropdown menu on the product page lets buyers select size, material, and pressure combinations tailored to their needs. Compliance with GB/T13927-92 ensures leakage rates stay below 0.1% of rated capacity.

Material Composition

HANUMAN offers customizable material packages:

- Valve Body: Ductile steel + NBR for cost-sensitive applications; stainless steel + NBR for corrosive media.

- Butterfly Plate: Options range from gray cast iron to specialty alloys for extreme temperatures.

- Stem: 2Cr13 or 316 stainless steel for wear resistance.

This flexibility ensures compatibility with water, oils, and mildly corrosive fluids.

Pneumatic Actuator and Control

Actuator Series

GT/AT/AW series actuators support both single-acting (spring-return) and double-acting configurations. Single-acting models fail-safe to open/closed positions during air supply loss—critical for fire protection systems. Double-acting types provide higher torque for heavy-duty cycles.

Air Supply Requirements

Standard operating pressure is 0.4–0.7 MPa, with multiple interface sizes (G1/4” to G1/2”) to match existing pneumatic lines. Accessories like positioners enable precise flow modulation, while solenoid valves facilitate on/off control. For harsh environments, HANUMAN’s actuators operate reliably from -30°C to +70°C.

Applications Across Industries

These valves excel in:

- Water Treatment: Controlling raw water intake and sludge lines.

- Oil & Gas: Isolating sections of gas pipelines with zero leakage.

- Pharmaceutical: Meeting FDA-grade cleanliness in CIP/SIP processes.

In China’s booming industrial sector, HANUMAN’s valves are trusted by factories for their consistent performance in paper mills, power plants, and chemical processing units.

Choosing the Right Valve: Pneumatic vs. Electric

Pneumatic actuators outperform electric ones in explosive atmospheres (ATEX-certified options available) and high-speed cycling (100,000+ cycles). They’re also more economical for large-scale installations. However, electric actuators offer finer control for gradual throttling. For most industrial buyers, the 6-inch stainless steel pneumatic butterfly valve hits the sweet spot between cost, speed, and durability.

HANUMAN’s D671X/D641X series combines premium stainless steel construction with precision engineering, delivering unmatched reliability for critical applications. As a leading manufacturer in China, we invite global partners to explore our factory-direct solutions—contact us today for customized quotations or technical support.

Product overview

The pneumatic soft-seal butterfly valve is composed of a pneumatic actuator and a center-line seal butterfly valve. The soft-seal butterfly valve is divided into two structures: wafer type and flange type.

Specifications

|

Nominal diameter

|

DN50-DN800 mm

|

|

Nominal pressure

|

0.6 MPa

|

1.0 MPa

|

1.6 MPa

|

|

Sealing test

|

0.66 MPa

|

1.1 MPa

|

1.76 MPa

|

|

Strength test

|

0.9 MPa

|

1.5 MPa

|

2.4 MPa

|

|

Proper temperature

|

Nitrile rubber: -30℃~80℃

|

|

Applicable media

|

Water, air, natural gas, oil and weakly corrosive fluids

|

|

Leakage rate

|

Conforms to GB/T13927-92 standard

|

|

Drive mode

|

Pneumatic

|

|

Configuring actuator

|

GT, AT, AW series of single and double acting pneumatic butterfly valve actuators

|

|

Control method

|

Switch two-position control, 4-20mA analog signal control

|

|

Part name

|

Material

|

|

Valve body

|

Ductile steel+NBR, cast steel+NBR, stainless steel+NBR

|

|

Butterfly plate

|

Gray cast iron, ductile iron, cast steel, stainless steel and special materials

|

|

Valve stem

|

2Cr13, stainless steel

|

|

Filter

|

O ring, flexible graphite

|

|

Actuator

|

GT, AT, AW series of single and double acting pneumatic butterfly valve actuators

|

|

Air supply pressure

|

0.4 to 0.7 MPa

|

|

Air source interface

|

G1/4”, G1/8”, G3/8”, G1/2”

|

|

Ambient temperature

|

-30 to +70 ℃

|

|

Action form

|

Single-acting, double-acting

|

|

Available accessories

|

Positioner, solenoid valve, air filter pressure reducer, position-holding valve, travel switch, valve position transmitter, handwheel mechanism, etc.

|

Overall dimensions

You can check sizes of these two models of wafer and flange type of stainless steel pneumatic butterfly valves and confirm that which size is suitable for you.

|

Nominal diameter (DN)

|

Main dimension (mm)

|

Flange size (mm)

|

|

L flange

|

L1 wafer

|

H

|

H1

|

A

|

1.0 MPa

|

1.6 MPa

|

|

D

|

D1

|

n-Ød

|

D

|

D1

|

n-Ød

|

|

50

|

108

|

43

|

63

|

315

|

180

|

165

|

125

|

4-18

|

165

|

125

|

4-18

|

|

65

|

112

|

46

|

70

|

330

|

180

|

185

|

145

|

4-18

|

185

|

145

|

4-18

|

|

80

|

114

|

46

|

83

|

390

|

245

|

200

|

160

|

4-18

|

200

|

160

|

8-18

|

|

100

|

127

|

52

|

105

|

431

|

240

|

220

|

180

|

8-18

|

220

|

180

|

8-18

|

|

125

|

140

|

56

|

115

|

455

|

240

|

250

|

210

|

8-18

|

250

|

210

|

8-18

|

|

150

|

140

|

56

|

137

|

626

|

350

|

285

|

240

|

8-22

|

285

|

240

|

8-22

|

|

200

|

152

|

60

|

164

|

720

|

350

|

340

|

295

|

8-22

|

340

|

295

|

12-22

|

|

250

|

165

|

68

|

206

|

800

|

550

|

395

|

350

|

12-22

|

405

|

355

|

12-26

|

|

300

|

178

|

78

|

230

|

860

|

600

|

445

|

400

|

12-22

|

460

|

410

|

12-26

|

|

350

|

190

|

78

|

248

|

883

|

600

|

505

|

460

|

16-22

|

520

|

470

|

12-26

|

|

400

|

216

|

102

|

289

|

972

|

600

|

565

|

515

|

16-26

|

580

|

525

|

16-26

|

|

450

|

222

|

114

|

320

|

1043

|

750

|

615

|

565

|

20-26

|

640

|

585

|

16-30

|

|

500

|

229

|

127

|

342

|

1098

|

750

|

670

|

620

|

20-26

|

715

|

650

|

20-30

|

|

600

|

267

|

154

|

413

|

1236

|

750

|

780

|

725

|

20-30

|

840

|

770

|

20-33

|

|

700

|

430

|

165

|

478

|

1431

|

750

|

895

|

840

|

24-30

|

910

|

840

|

24-36

|

|

800

|

470

|

190

|

525

|

1488

|

750

|

1015

|

950

|

24-33

|

1025

|

950

|

24-39

|